Chemical Storage Tanks With Secondary Containment

In the epa s regulations for hazardous waste treatment storage and disposal facilities the requirement specifically states that a secondary containment system must have sufficient capacity to contain 10 of the volume of the containers or the volume of the largest container whichever is greater 40 cfr 264 175 if the containment.

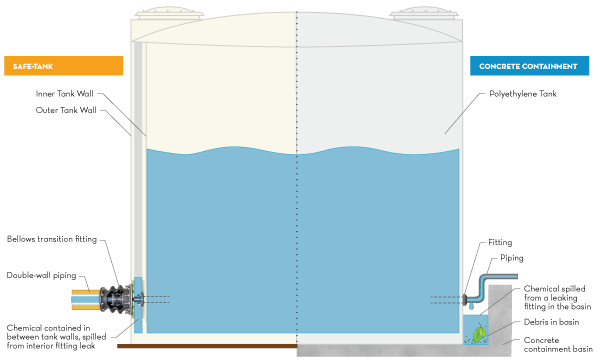

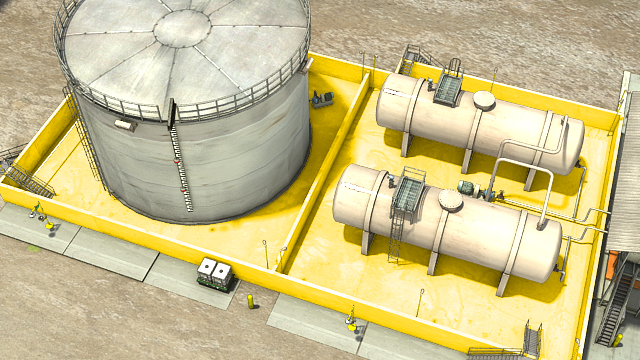

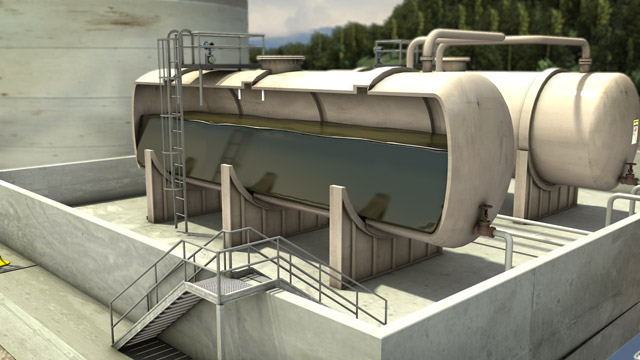

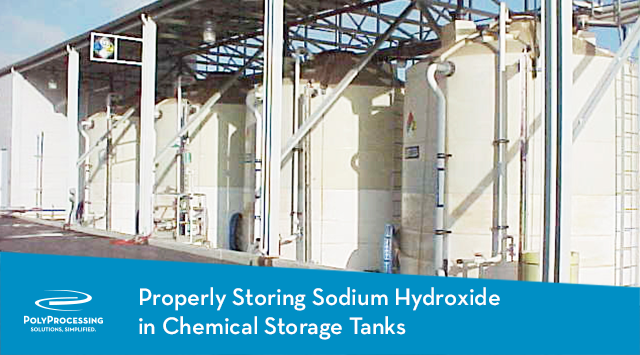

Chemical storage tanks with secondary containment. Chemical storage tanks with secondary containment if you are looking for a reliable device to keep oils chemicals and acids then chemical industrial storage tanks are the best. Houston polytank manufactures double wall tanks that are part of a larger chemical storage containment system where we create a plastic tank inside a plastic tank. These two tanks are welded together to create a double wall containment system that is then set in a secondary containment area in the facility. Doing so allows sufficient time for cleaning up the product before it moves beyond the secondary containment envelope and poses a more serious safety and environmental contamination hazard.

The epa refers to the need for containment and secondary containment in two different areas. In most cases secondary containment is used when the liquid being stored in the tank is either a hazardous chemical or a liquid that could pollute the local ground water supply. Secondary containment for asts is defined as capturing the entire contents of the largest tank in the containment area in the event of a leak or spill. Subpart i use and management of containers 40 cfr 264 175 which covers portable storage containers such as 55 gallon drums for hazardous waste and the second in subpart j tank systems 40 cfr 264 193 which covers large stationary containers.

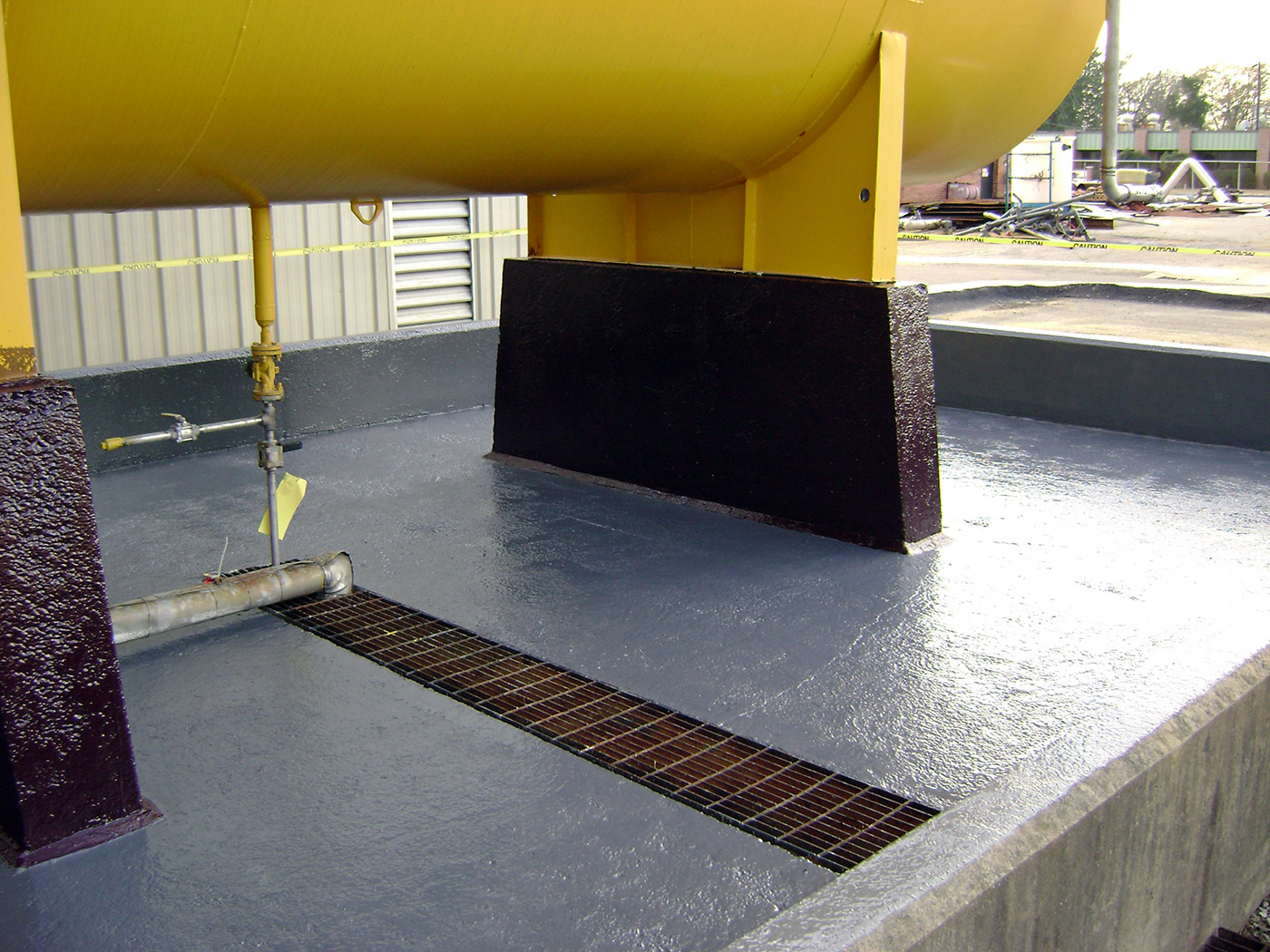

The secondary containment is designed with a flat floor the wall height is equal for all four walls and. Secondary containment refers to the ability to catch or contain a spill from a storage tank. The epa refers to the need for containment and secondary containment in two different areas. Available in different models and designs they are created perfectly to meet up different environmental requirements and regulations.

Inner tank dome overlaps outer tank sidewall to prevent rainwater snow and debris from entering into the containment basin. Additionally the calculations do not include displacement for support structures or foundations. Our ability to heat trace and insulate make these tanks perfect for temperature sensitive chemicals. The corners of the secondary containment system are 90 degrees.