Cross Flow Membrane Filtration System

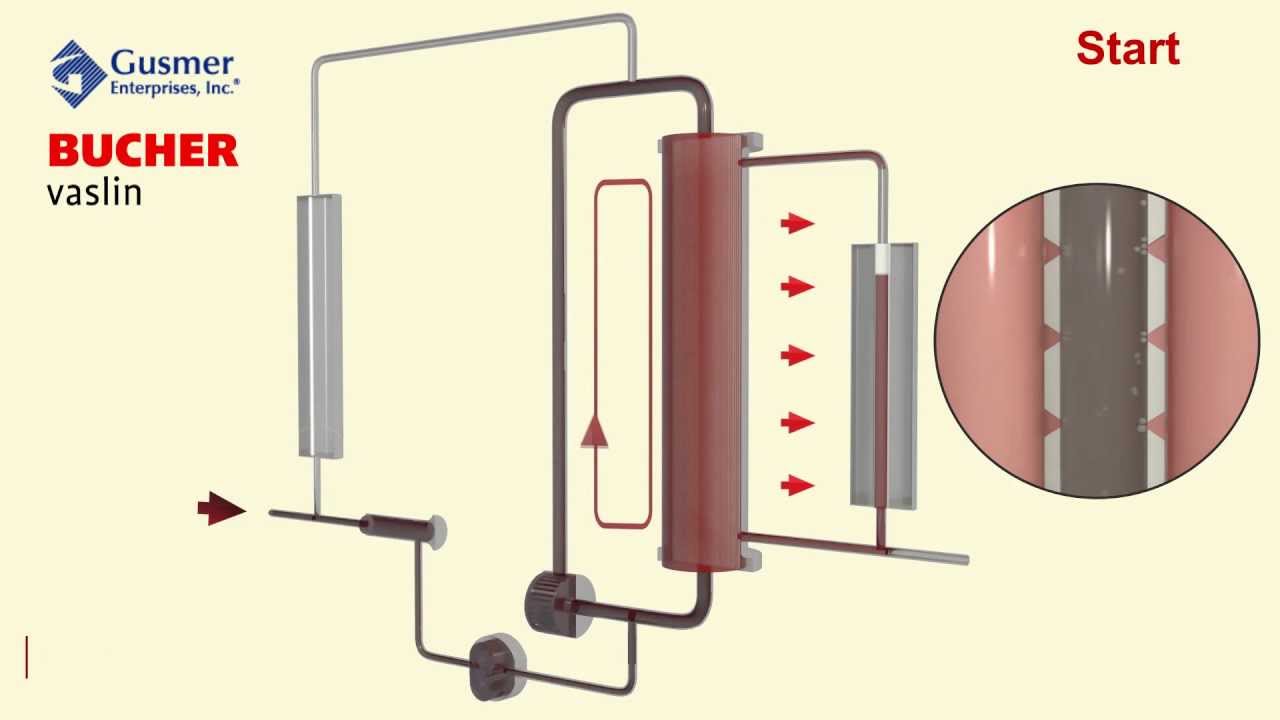

Cross flow filtration can also be used for pre treatment of cold sterlised unfermented must to replace a diatomaceous earth filter and a filter pad directly upstream of membrane filter cartridges in stainless steel cartridge housings for cold sterilisation of unfermented must.

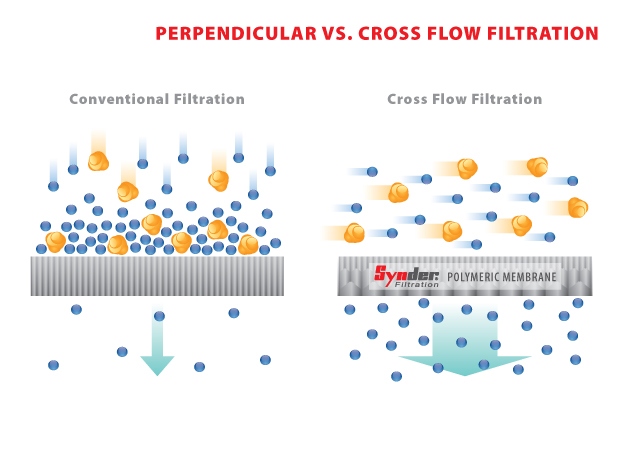

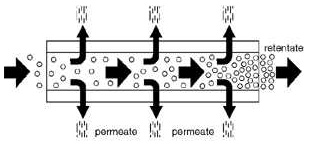

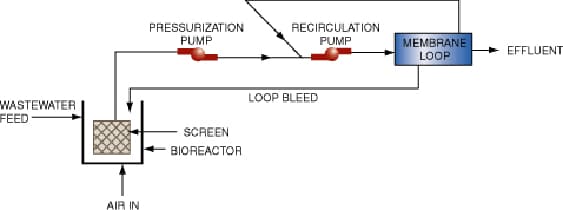

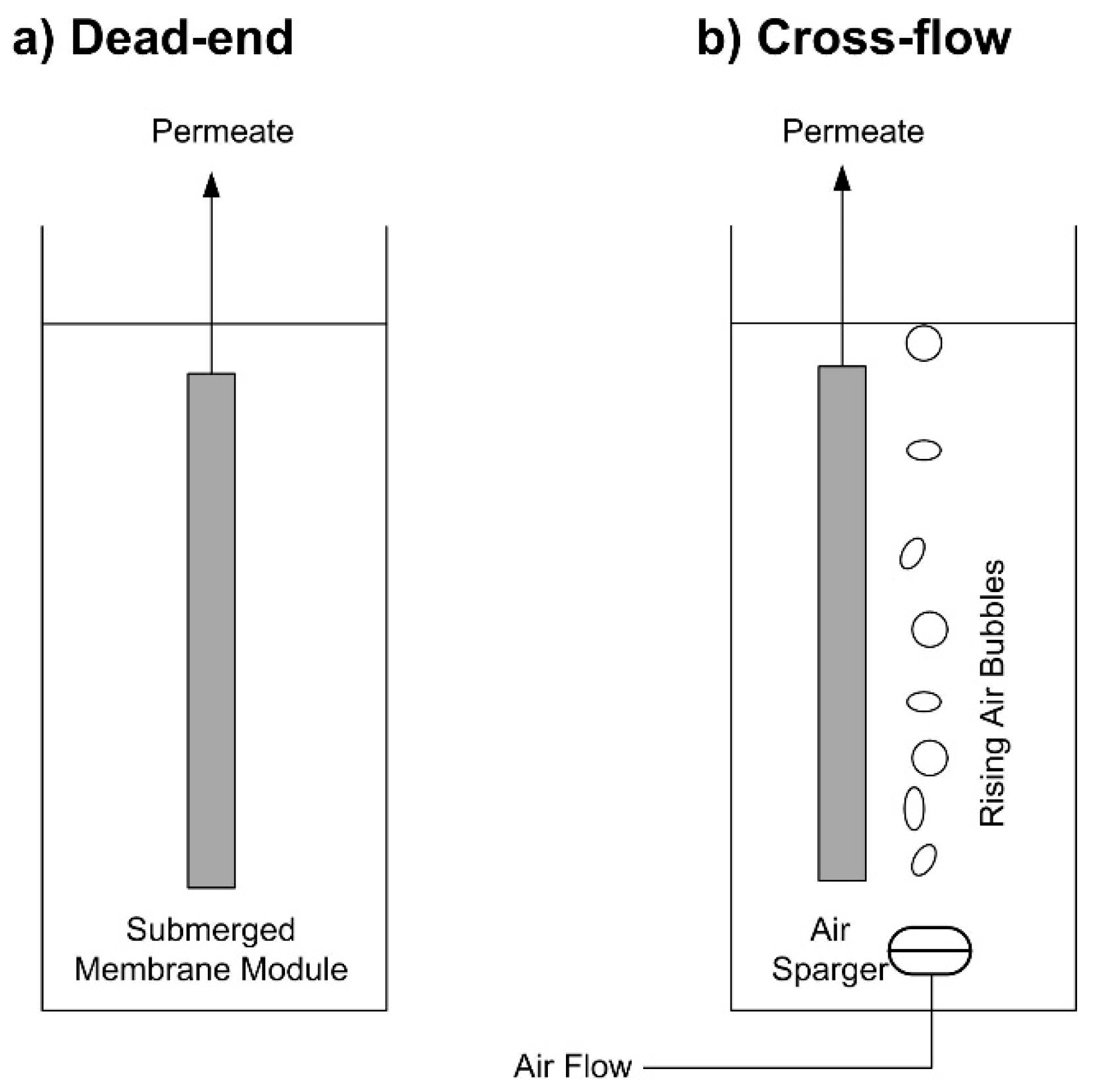

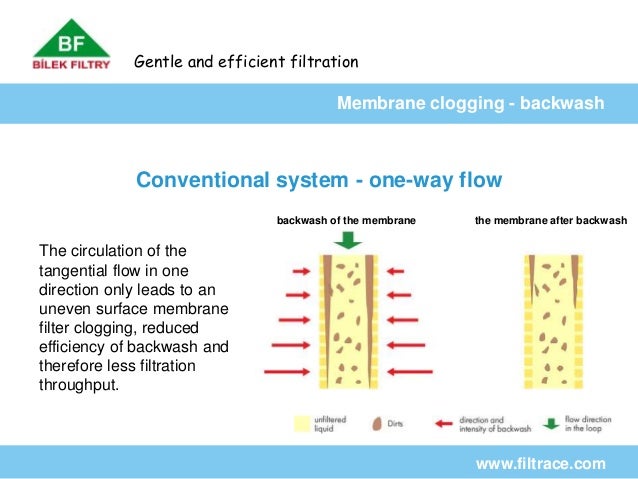

Cross flow membrane filtration system. Cross flow membrane filtration is the technology of choice for many industrial processes that require the separation or concentration of products without the application of heat. They feature electrocoat and sanitary spiral filter construction are suitable for industrial as well as food and beverage applications and comply with 3 a fda cfr title 21 and usda standards. Parker s cross flow membrane filters permit fluid to pass tangentially along filter surfaces to enable particle separation. The turbulence created across the membrane surface provides optimal flux performance and prolongs filter functionally.

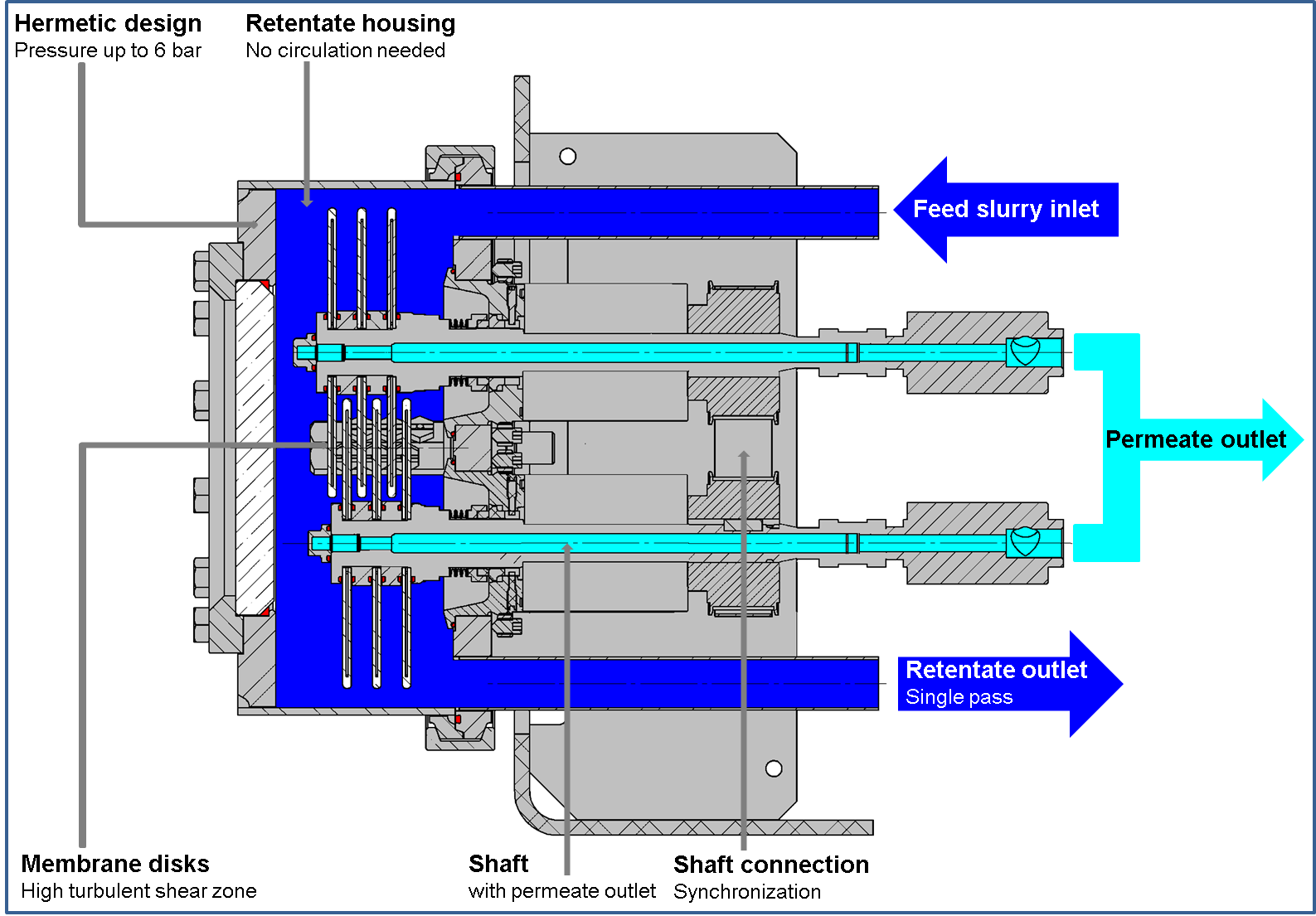

There are applications throughout the food dairy pharmaceutical biotechnology and starch and sweetener industries in which membrane filtration excels. These unique properties allow the 100 pure titanium. Titanium membranes are unbreakable and won t need replacing for the life of the machine. It is a process whereby product flow feed is directed tangentially along the surface of a membrane with most of the solution circulated back to the feed tank.

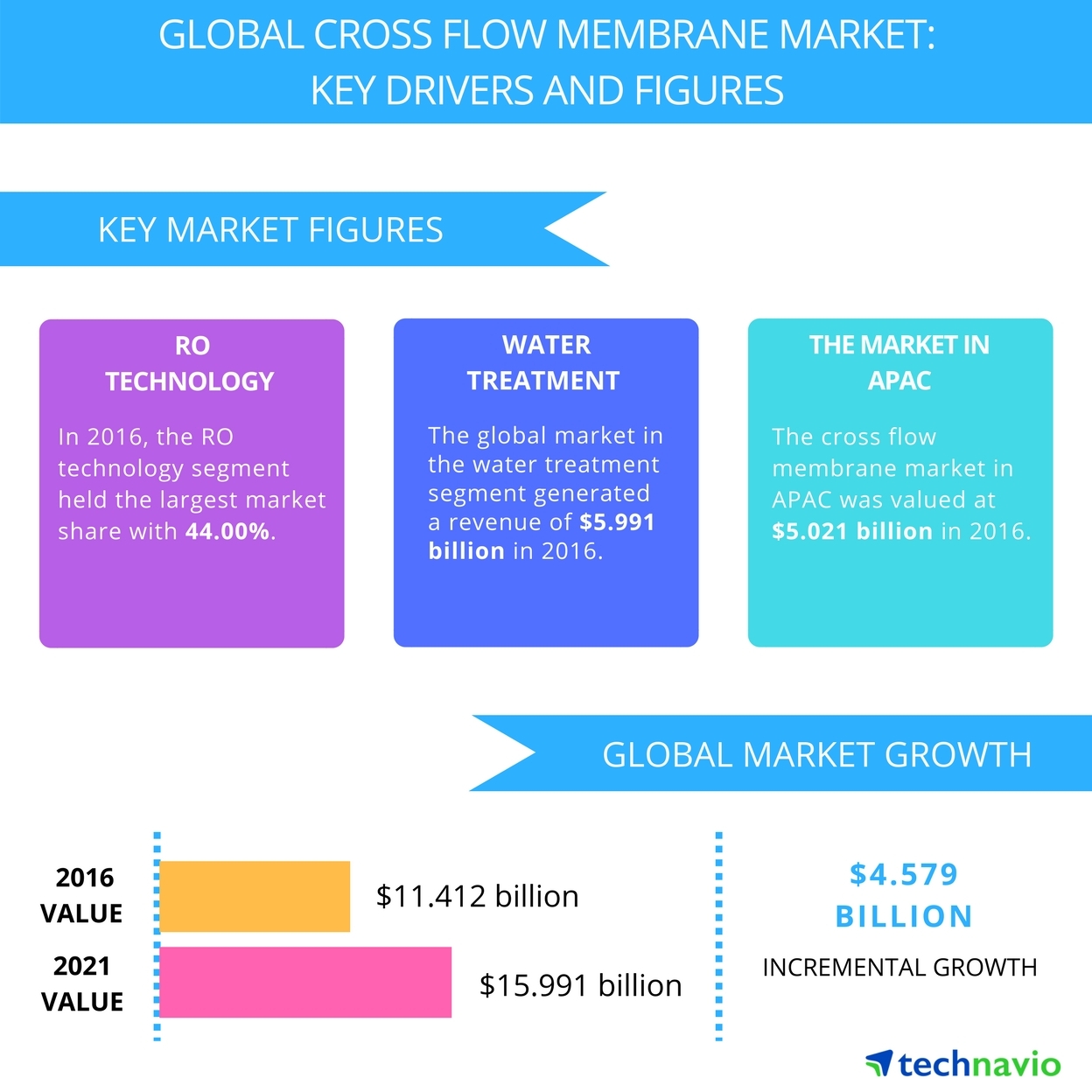

The principles of cross flow filtration are used in reverse osmosis nanofiltration ultrafiltration and microfiltration. Scepter membrane products are stainless steel cross flow membranes for extreme process conditions. Cross flow membrane filtration technology has been used widely in industry around the globe. They allow incredible high solids loading while allowing a massive range of filter pore size options at the same time.

2 cold sterilisation of unfermented must. Tangential flow filtration tff also called cross flow filtration cff is a rapid and efficient method for filtration and separation of solutions containing biomolecules or particles such as viruses bacteria or cellular material. Filtration membranes can be polymeric or ceramic depending upon the application. The heart of the product is a patented coating that provides a highly durable filter medium for superior separations and reliable performance even under the harshest conditions.